Limits & Fits | Types of Fits Explained & Tolerance Charts - Fractory

Aug 14, 2020 · Limits and fits are a set of rules regarding the measurements and tolerances of mating machine parts to achieve the best working conditions.

Standard Mechanical Tolerance Table Charts for Shaft - Hole Fits

The following links are to Mechanical Tolerance Table Charts for Standard Shaft Hole Fits per ANSI 4.1. The size ranges given are for typical size ranges utilized within industry.

H (h) Tolerances For Shafts and Holes - Full Charts - Machining …

Find your data faster with our Fits and Tolerance Calculator The Inch values shown in the table are conversion from the mertic values per ISO 286. you should expect about 0.1-0.5 thous errors wehn comparing with ANSI B4.1/4.2!

ANSI LIMITS, FITS AND TOLERANCES CALCULATOR - Amesweb

ANSI tolerance calculator is applicable to non-threaded cylindrical parts. Limits of sizes that calculated are the extreme values, within which the actual size of the dimension shall lie, at the standard temperature of 20C or 68F.

LIMITS AND FITS CHART - machinecharts.com

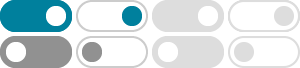

SLIDING FIT: Not intended to run freely, but to move and turn and locate accurately H7/h6 LOCATION FIT: Snug fit for staitonary parts, can be freely assembled and dissassembled

Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron. Force fit suitable for parts which can be highly stressed or for shrink fits where the heavy pressing forces required are impractical. Loose running fit for wide commercial tolerances or allowances on external members.

Fits with great clearances with parts having great tolerances. Running fits with greater clearances without any special requirements for accuracy of guiding shafts. Multiple fits of shafts of production and piston machines, parts rotating very rarely …

Preferred Tolerances & Fits Chart ANSI B4.1 Table Calculator RC - LT Fits

This Calculator will determine the preferred size and limit tolerances for Running or sliding to interference-locational fits per ANSI B 4.1.

Fitting Clearance Fit Transition FitInterference Fit Clearance FitInterference Fit ... Clearance Fit Transition Fit Interference Fit Clearance Fit Clearance Fit Clearance Fit Class of Tolerance Range for Shafts f6 g5 g6 h5 h6 js5 js6 k5 k6 m5 m6 n6 p6 e7 f6 f7 g6 h6 h7 js6 js7 k6 m6 n6 p6 r6 s6 t6 u6 x6 d9 e8 e9 f7 f8 h7 h8 c9 d8 d9 g8 e9 h8 h9 ...

Engineering Fits & Tolerances – Calculator & Charts - Machining …

Our smart WIZARD shows you the BEST GRADE by each brand for your application! Technical drawings often include notations such as “50 g6” or “17.5 H11/g8” to specify tolerances. However, determining the final limits can be time-consuming and involve navigating complex charts.